How Does a Shallow Well Pump Work with a Pressure Tank

Most urban households are connected to a central water distribution system. However, rural homes don’t have the same privilege. Since they tend to be on the outskirts of the city, it isn’t feasible to connect them to the main system, and they are often left to fend for themselves.

Consequently, hundreds of thousands of houses get their water from well pumps. If you live on one of these properties, it can be helpful to learn how the system works.

This way, you'll know what each component does and be prepared if there is a need to make repairs. Also, you will be able to troubleshoot in case of emergencies and take appropriate actions.

25+ Years of Shallow Well Experience

After installing thousands of shallow well systems across North America, I've learned that understanding how these systems work with pressure tanks is critical for long-term success. Most customers ask me the same questions about pressure tank operation, cycling, and troubleshooting.

The key insight from 25+ years of installations: pressure tank sizing and proper cycling are more important than pump horsepower for shallow well applications.

Real Customer Scenarios

RV Park in Georgia: 100-foot installation serving multiple sites. Customer integrated Simple Pump with existing pressure tank system for backup during power outages. Result: "Less than two hours installation time and kept the motor home full with water for showers and dishes with just 100 pumps."

Weekend Cottage in Maine: Seasonal use property with shallow well and net-zero energy requirements. Hand pump charges pressure tank for indoor plumbing during off-grid periods. Perfect integration with existing electrical system.

Well Pumps

Before anything else, you should have some general information about well pumps and what they are. For more in depth information, please see our Well Pump Buyer's Guide or use our system configurator to find the right pump for your well.

In order to access an underground water table, you need to first drill a well and then install a water pump to lift the water into your home. There are different types of well pumps, the right one for you depends on the depth of your well.

The number of people in your home, the water demand, and the number of plumbing fixtures also affect the well pump you purchase. Depending on how much water you need and how far you need to transport it, your pumping requirements will change.

A shallow well pump is ideal for wells with static water depths equal to or less than 25 feet. They aren't very deep because the water table is close to the surface. Moreover, you don't need a lot of power since the water doesn't need to be moved across a long distance.

Types Of Shallow Well Pumps

There are two main types of well pumps appropriate for shallow wells: hand pumps and electric pumps like a jet pump or a submersible pump. Each one has its own mechanism for getting water from under the ground into your home. Consequently, the requirements and maintenance demands also change depending on the pump type.

Shallow Well Hand Pump

A hand pump doesn’t need electricity to work. Instead, you are responsible for generating energy for it through a pumping motion.

Homeowners like to get hand pumps to supplement their water supply in case of a power outage because in such situations relying entirely on pumps working on electricity can leave them without water. Hence, its mechanism utilizes a pumping motion to create a suction to lift the water which is very different from both jet and submersible pumps.

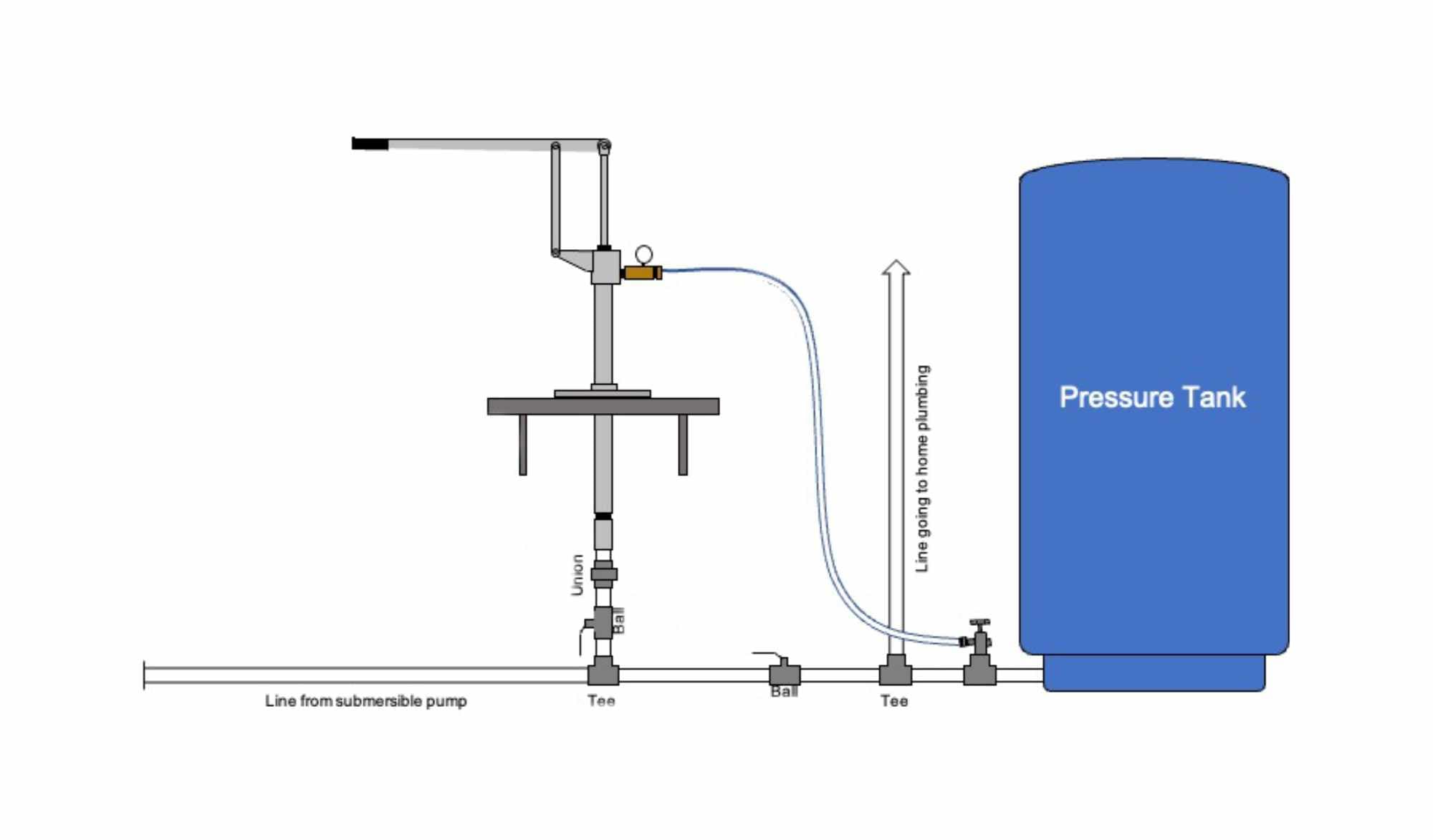

The Simple Pump Shallow Well Suction Pump can pump water from your well into a pressure tank. A check valve/pressure gauge is utilized when pumping into pressure to understand how full the tank is.

Electric Shallow Well Pumps

Here is everything you need to know about how the two types of electric well pumps with pressure tanks work.

Shallow Jet Pump

The most common type of shallow pump these days is a jet pump. It is installed above the ground. Some people build a storage shed or house specifically for it if their well is far away from their house.

However, if the house is close by, it can be easier to mount the well inside.

Since jet pumps are above the water, they have to pull it up to the ground. They use a special kind of suction mechanism to get the job done.

The easiest way to explain it is by thinking about drinking water with a straw. You suck on a straw and get water in your mouth, but the physics behind the process is more complicated than that.

You create a vacuum by sucking on the straw. Then the weight of the air pushes the water up to your mouth. It’s all about manipulating atmospheric pressure. Jet pumps use the same basic physics principle of ‘suction’ to pull up water.

The specific process is, of course, a little different.

These pumps run on electricity, so their centrifugal pump or impeller is driven by an electric motor that pushes water from the well into a narrow orifice. The water speeds up as it passes through this orifice because it is constricted towards the end.

As soon as the water leaves this orifice, a vacuum is created. This vacuum sucks up more water from the well and pulls it up.

There is a Venturi tube right behind the narrow orifice. It increases in diameter, and water passing through it slows down, which increases its pressure. At this point, the drive water and pumped water combine and discharge from a faucet with high pressure.

Shallow Submersible Pump

The second type of well pump for wells equal to or less than 25 feet deep is the submersible pump. While it is typically used for deeper wells that run several hundred feet deep, you can use it for shallower ones too.

Submersible pumps are effective because they’re placed inside the well instead of aboveground. This means that the pumps push water up as compared to the jet pump pulling it.

The bottom half of a submersible pump is made up of a sealed pump motor which is connected to a power source above the ground. This is usually an electric generator.

The other half is a series of stacked impellers. Each is separated by a diffuser that drives water up the pipe into your plumbing system.

General Pump Characteristics

Irrespective of which type of shallow well pump you purchase, there are some common characteristics. For instance, no well pump runs continuously. The pump runs for a while until the water storage tank fills. The pump then turns off or you can stop hand pumping.

Modern tanks have air bladders that give them the signal to start and turn off. This bladder compresses as water is pushed in. Once the pressure reaches a certain pre-decided number (somewhere between 40 and 60 psi), the pump stops.

As you use water, the pressure drops. As soon as it reaches another pre-decided number (around 20 psi), the pump starts again and begins pushing water into your water tank.

Therefore, the pressure tank is one of the most important components of any shallow well pump.

Another common characteristic is run time. Most well pumps take 1 to 2 minutes to cycle. One cycle defines the process of pulling (jet pump) or pushing (submersible pump) water into the storage tank until it is full.

Pressure Tanks Problems

Since a well pump’s pressure tank is integral to its functioning, it is important to make sure it works properly. If it stops doing so, you’ll face a problem known as short cycling.

Short cycling is when your well pump turns on and off quickly and has a shorter run time than normal. Since your pump uses a lot of power to turn on and off, doing so more than needed can damage its motor. Additionally, it can lead to overheating, which reduces your pump's life.

Needless to say, you will want to avoid short cycling wherever possible.

How to Diagnose Short Cycling

The easiest way to tell if your pump is short cycling is by checking its run time. Take a stopwatch and record how long your pump cycles for. If this is shorter than the expected time period on your user’s manual, you need to troubleshoot and fix the issue to restore normal function.

It can be difficult to tell whether a submersible pump is running or not. However, these pumps have relay switches that click on and off when the pump is active. If you pay close enough attention, you will be able to hear it.

Some models have a relay switch light which makes identifying the action easier.

The Most Common Causes of Short Cycling and How to Fix Them

- Losing Air Charge

It is very common for older pumps to lose their air charge. If this happens, they start short-cycling and decreasing their already limited life span.

You can fix the issue by cleaning your air volume control valve. If that doesn’t work, take some water out of your tank to make space. Then use a bicycle pump and water tank air inlet to pump air into it.

- Problems With The Water Pump Control Switch

Another common cause of short cycling issues is the water pump control switch. It can get blocked with debris and sediments very easily. This leads to the school being wrongly adjusted and your well pump cycling too much.

The only way to fix this issue is to replace your water pump control switch. You can find compatible replacement parts in our parts catalog or contact the nearest hardware store and get a new one as soon as possible.

- Blocked Water Pipes

In addition to damaging water pump control switches, debris can also block water pipes. When that happens, there is a build-up of pressure, and your well pump turns off before the water storage tank has filled.

You can confirm if blocked water pipes are causing the short cycling by looking at your water filter. If it is dirty or leaking, you’ve found the root of the problem.

The easiest way to fix the problem is to replace the damaged water pipes. However, remember that if debris got into the pipes, it probably also got into your switch. These two issues usually, but not always, go hand in hand.

Therefore, we’d recommend looking at the switch and seeing if it needs to be changed.

That's all you need to know about how a shallow well pump with a pressure tank works!

Professional Installation & Support

Whether you're installing a new shallow well pump or troubleshooting an existing system, our experts can help you choose the right solution for your specific well conditions.

Get System Recommendation - Professional consultation for your shallow well

Find Local Installer - Certified installation services in your area

Ready to Get Started?

Installing a Simple Pump system is easier than you think. Request a free quote to get a custom system recommendation for your well, or contact our experts for personalized guidance.

Questions about installation? Call us at (877) 492-8711 or find a certified dealer near you for professional installation support.

Tags:

Ready to Get Started?

Get expert help choosing the right well pump system for your specific needs. Our team has 25+ years of experience in reliable water systems.