How Difficult Is It to Pump a Simple Pump Hand Pump

After 25+ years of customer installations, the #1 question families ask is: "Will I actually be able to operate this pump?" The answer depends on proper system design, not just your physical strength.

Critical Customer Reality: Properly designed Simple Pump systems are successfully operated by customers ranging from 60-year-old women to families with disabled members. The key is understanding how pump design affects real-world usability.

Real Customer Success Examples:

- 60-year-old, 100-pound woman: Successfully operates pump from 140-foot well "while sitting in a chair"

- Maine family: Wife found competitor Bison pump "very hard to use" but Simple Pump "extremely easy to operate"

- Multiple customer reports: Installation and operation easier than expected due to lightweight fiberglass rod design

Professional Insight: Customer success depends more on proper system configuration than individual strength. I'll show you exactly how to calculate your specific requirements and optimize for accessibility.

Real Customer Accessibility Success: What Actually Works

25+ Years of Customer Reality: Age and physical strength matter far less than proper system design. I've seen 80-year-old customers operate pumps that 30-year-olds struggle with poorly designed competitors.

Customer Success Pattern: Families who choose properly configured systems report that pump operation becomes routine and manageable, even for family members with physical limitations.

Accessibility Design Advantage: Simple Pump's lightweight fiberglass rods weigh significantly less than competitors' steel rods, reducing the total weight lifted with each stroke. This engineering choice makes the difference between accessible and inaccessible operation.

Total Dynamic Head Calculation:

Understanding the pumping effort starts with calculating theTotal Dynamic Head (TDH) of your pumping system. Total Dynamic Head represents that work that needs to be done by the pump to move water from your well to its point of use. TDH is represented in vertical feet of water that that needs to be pumped. You can easily calculate the TDH of your pumping system by knowing three factors: the static water level of your well, the vertical rise to your point of use, and the pressure you are pumping into (if pumping into pressure). We go into each of these in more detail below, but simply add all three together to calculate your system’s TDH.

S – Static Water Level (in feet)

R – Vertical Rise (in feet)

P – Pressure You Are Pumping Into (converted from PSI to feet)

TDH = S + R + P

Static Water Level:

Static water level is the depth at which water sits below the ground in your well and directly influences the pumping effort. Simply put, the deeper the water, the more effort it takes to bring it to the surface. By understanding your well's static water level, you can better predict the effort needed for pumping.

Vertical Rise:

Vertical rise refers to the elevation difference between the well head and the point of use. This difference can increase or decrease your system’s TDH depending on whether the use point is above or below the wellhead. Due to relatively low pumping velocities, horizontal distance from the well head to the point of use typically has little impact on TDH for most SimplePump applications. Horizontal distance only impacts TDH if the horizontal run is excessively long (>200 feet) or the horizontal pipe/hose has a small inside diameter (<0.5 inches).

Example 1: Your wellhead is 20 feet below and 40 feet away from the cistern. In this example, you would need to add 20feet to your system’s TDH.

Example 2: Your wellhead is 24 feet above and 100 feet away from your basement where your home pressure tank is. In this example you would need to subtract 24 feet from your TDH.

Pressure:

If you are pumping water into a pressurized system, your system’s Total Dynamic Head (TDH) is increased due to that pressure.

Convert the system’s pressure from PSI (pounds per square inch) into feet of head by multiplying the pressure in PSI by 2.31. Due to the weep hole in our system, the maximum pressure the Simple Pump can pump into is45PSI.

For example, if you are pumping into a pressure tank that is pressurized to 35 PSI, then add 81 feet (35*2.31) to your system’s TDH.

Remember, as the pressure you are pumping into increases, so does the effort needed to pump.

Total Dynamic Head Calculation Example:

For example, if your static water level is 80 feet, vertical rise is 10 feet and you are pumping into a pressure tank at 20 psi, your TotalDynamic Head is 136.2 feet.

TDH = S + R + P

TDH = 80 feet + 10 feet + 20*2.31 feet

TDH = 136.2 feet

Optimizing Pump Effort

Volume Per Stroke and Mechanical Advantage:

Though your well's static water level, location, and the laws of physics are beyond your control, you can still make pumping easier.When you request a quote, we'll recommend a pumping cylinder and handle length tailored to your needs. Here's how you can adjust for easier pumping.

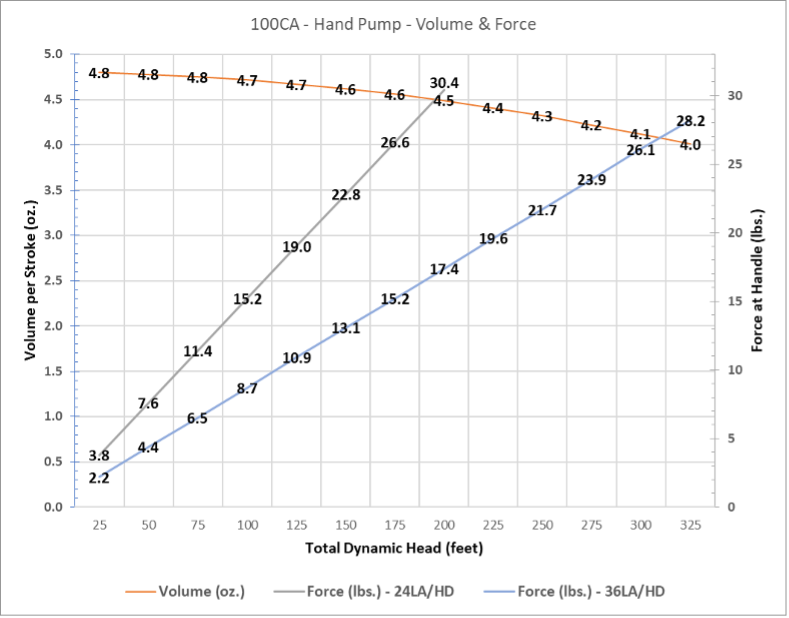

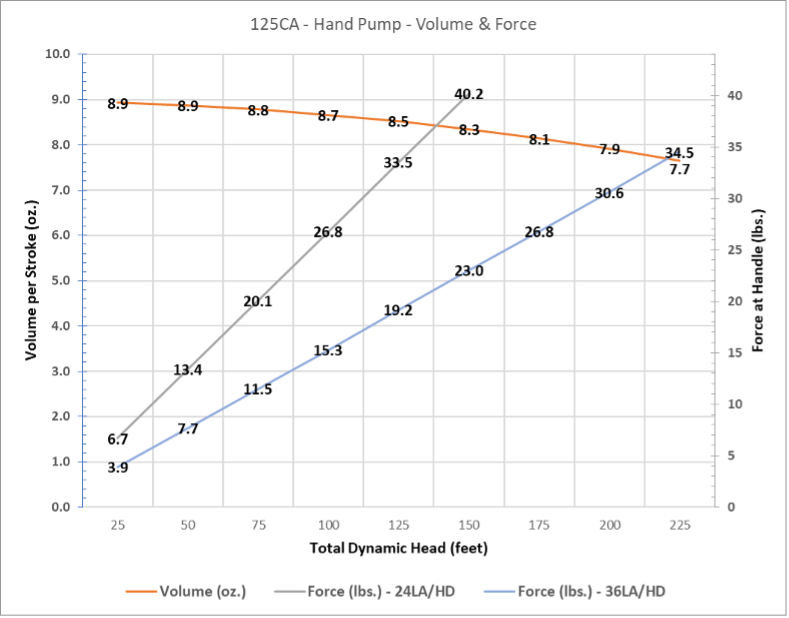

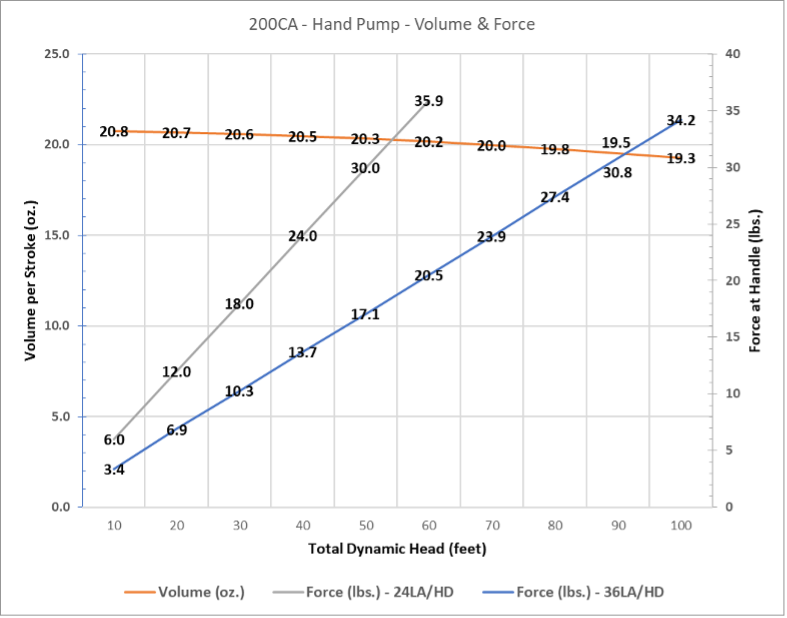

- Choose the Right Pumping Cylinder: The size of the pumping cylinder affects how much water you pump with each stroke. A smaller cylinder means less water per stroke, reducing effort. We offer cylinders suited for various pumping capacities. Your quote will guide the best fit for your situation. We offer three different pumping cylinders: 100CA, 125CA-82515 and 200CA with maximum volumes per stroke of 4.5 ounces, 8.5 ounces, and 20 ounces, respectively. The Total Dynamic Head of your system limits which size cylinder you can use. The 100CA cylinder is limited to a TDH of 325 feet. The 125CA-82515 cylinder is limited to a TDH of 225 feet. The 200CA cylinder is limited to a TDH of 110feet. See the charts at the end of this article for details on the effort differences between the pumping cylinders.

- Optimize Lever Arm Length: The length of the lever arm influences the effort required to pump water. Longer arms provide more mechanical advantage, requiring less downward force applied at the pump handle. We'll suggest the optimal lever arm length for your setup, but switching to a longer arm could further ease the pumping process. We offer two different lever arms: 24LA (24”in length) and 36LA (36” in length). The24LA provides a 3-to-1 mechanical advantage, while the 36LA offers a5-to-1. This means a 36LA requires less downward force than a 24LA. See the charts at the end of this article for detail on the downward force differences between the lever arms.

By considering these adjustments, you can optimize water flow and pumping effort for your system.

Managing Effort with Pumping Pace:

Controlling your pumping pace is a practical way to manage effort. Faster pumping requires more effort. A slower, steady pace makes pumping more manageable.

Optimizing Pump Performance with TDH, Cylinder, and Handle Calculations:

The charts below provide the water volume per stroke and the required downward force applied to the handle for different cylinder and handle options.

Volume per Stroke

As Total Dynamic Head increases, water volume per stroke slightly decreases a result of rod stretch. The graphs below show the water per stroke for each cylinder at different system TDH heights (in feet). This information helps you accurately predict the water flow rate that you will be able to pump, guiding your choice of pumping cylinder based on your specific needs.

Force Applied on the Handle

The charts below show force calculations (in pounds) for the different cylinder and handle options. These charts show the downward force that will need to be applied to the handle at different system TDH (in feet).

By consulting the charts below, you can determine the most suitable pumping cylinder and handle combination for your needs, ensuring optimal balance water flow and effort during use.

Figure 1: 100CAVolumes and Force at Handle

Figure 2: 125CAVolumes and Force at Handle

Figure 3: 200CAVolumes and Force at Handle

Professional Assessment: Your Pump Will Be Easier Than You Think

25+ Years of Customer Reality: Properly configured Simple Pump systems consistently exceed customer expectations for ease of operation. The combination of lightweight fiberglass rods, optimized mechanical advantage, and precise system sizing makes pumping accessible for virtually any family member.

Customer Success Formula:

- Proper TDH calculation ensures system is sized for your actual conditions

- Optimal cylinder selection balances water flow with pumping effort

- Correct handle length provides appropriate mechanical advantage

- Professional consultation prevents over-sizing that increases effort unnecessarily

Real Customer Validation: Every accessibility success story follows the same pattern - customers initially worried about pump difficulty discover that proper design makes operation manageable and routine.

Professional Recommendation: Don't let concerns about physical effort prevent you from achieving water security. With proper system configuration, Simple Pump operation becomes as routine as any household task.

Customer Quote: "I was worried about being able to pump from 140 feet. Now I pump while sitting in my chair and it's no big deal." - 60-year-old customer with accessibility needs

Ready to Get Started?

Installing a Simple Pump system is easier than you think. Request a free quote to get a custom system recommendation optimized for your well and family accessibility needs.

Questions about pump effort or accessibility? Call us at (877) 492-8711 to speak with our experts who've helped hundreds of families configure accessible pump systems.

Ready to Get Started?

Get expert help choosing the right well pump system for your specific needs. Our team has 25+ years of experience in reliable water systems.